Introduction

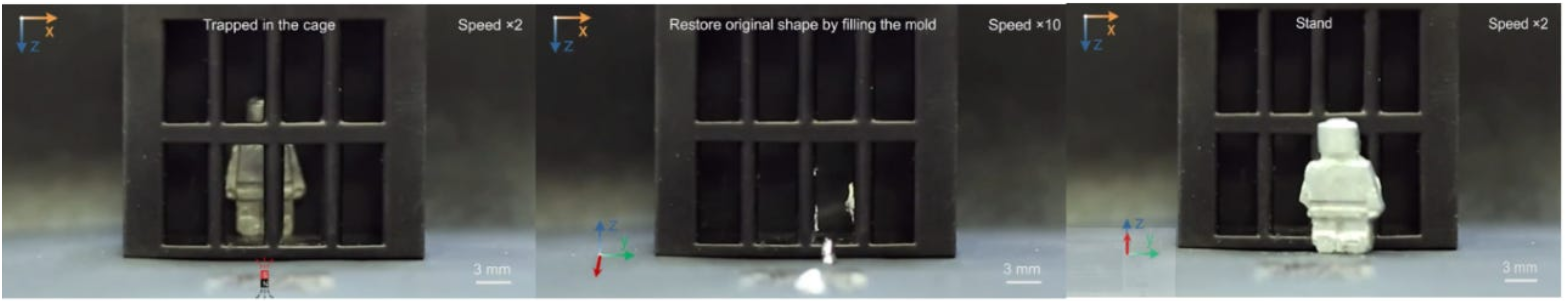

Recently, scientists from the Chinese University of Hong Kong have generated a metal microbot made of magnetoactive phase transitional matter (MPTM) that can be steered and reshaped by heating with an alternating external magnetic field or through ambient cooling. They experimented with a tiny robot molded in the shape of a Lego minifigure that could move and escape from an extremely small cage by melting, sliding through secure bars, and then reforming into solid and complete tasks. These machines can significantly change their shape, allowing them to navigate through narrow and confined spaces such as cavities or organs within the human body, and accomplish multiple tasks including targeted cargo delivery, which can’t be done with their solid counterparts. According to the researchers behind this project, these material systems can make a breakthrough in producing super flexible electronics, healthcare equipment, and robotics.

Main Text

The metal microbot developed by the researchers is constructed using magnetoactive phase transitional matter, a novel material that exhibits transformative properties when subjected to external stimuli such as magnetic fields or temperature changes. Unlike conventional rigid robots, this microbot can undergo dramatic shape changes, transitioning from a solid state to a liquid state and vice versa. This unique characteristic enables it to navigate through confined spaces with ease, making it ideally suited for applications in fields such as healthcare, electronics, and robotics.

In their experiments, the researchers molded the metal microbot into the shape of a Lego minifigure, demonstrating its ability to move and escape from a confined environment. By utilizing external magnetic fields or ambient cooling, the microbot can melt, allowing it to slide through narrow gaps or bars, and subsequently reform into a solid state to perform tasks. This remarkable capability opens up a myriad of possibilities for applications in various industries, where traditional rigid robots would be impractical or ineffective.

One of the key advantages of the metal microbot is its ability to navigate through narrow and confined spaces, including cavities or organs within the human body. Traditional robotic systems often struggle to access such areas, limiting their utility in medical procedures or targeted interventions. However, with the advent of liquid metal microbots, these limitations can be overcome, paving the way for advancements in minimally invasive surgeries, drug delivery, and diagnostic procedures.

Furthermore, the microbot's ability to perform tasks in both its solid and liquid states offers unprecedented versatility and functionality. It can carry out complex maneuvers, such as targeted cargo delivery or precise manipulation of objects, with ease. This versatility makes it an invaluable tool in a wide range of applications, from assembling electronic components in tight spaces to performing intricate surgical procedures with precision and accuracy.

The potential applications of the metal microbot extend beyond healthcare and robotics. In the field of flexible electronics, for example, these microbots could be used to assemble and repair delicate electronic components with unparalleled precision. They could also be deployed in disaster response scenarios, where their ability to navigate through narrow and hazardous environments could prove life-saving.

Overall, the development of the metal microbot represents a significant milestone in the field of robotics. Its transformative capabilities, coupled with its versatility and adaptability, make it a game-changer in various industries. As researchers continue to explore the potential of liquid metal smart materials, we can expect to see further innovations that push the boundaries of what is possible in robotics and beyond.

Conclusion

In conclusion, the creation of a metal microbot using magnetoactive phase transitional matter marks a significant advancement in robotics. This innovative technology offers unprecedented flexibility, maneuverability, and functionality, with applications spanning healthcare, electronics, and beyond. As researchers continue to push the boundaries of liquid metal smart materials, we can anticipate further breakthroughs that revolutionize the way we approach robotics and technology.